Nikola Tesla Patents

Nikola Tesla British Patent 2812 - Improvements in Methods of and Apparatus for the Generation of Electric Currents of Defined Period

| No 2812 | A.D. 1894 |

(Under International Convention.)

Date claimed for Patent under Sect 103 of Act, being date of first Foreign Application (in United States), - 19th Aug., 1893

Date of Application (in United Kingdom), 8th Feb., 1894

Complete Specification Left, 8th Feb., 1894 - Accepted, 10th Mar., 1894

COMPLETE SPECIFICATION.

Improvements in Methods of and Apparatus for the Generation of Electric Currents of Defined Period

I, Nikola Tesla, of 35 South Fifth Avenue, New York, County and State of New York, United States of America, Electrician, do hereby declare the nature of this invention, and in what manner the same is to be performed to be particularly described and ascertained in and by the following statement:-

This invention consists in producing electric currents of constant period by means of an engine and an electrical generator which are so constructed and related that (a), the engine of itself is capable of imparting to the moving element of the generator an oscillation of constant period, or (b) the period of reciprocation of the engine and the natural rate of vibration of the electric system will so nearly approximate as to act in resonance, or, (c), the engine, while fully capable of maintaining a vibration once started has not the power to change its rate so that the electric system will entirely control its period.

A description of the engine proper which has the property of running with a constant period is necessary to a complete understanding of the present invention. The following conditions are to be observed in order to produce such an engine.

It is a well known mechanical principle that if a spring possessing a sensible inertia be brought under tension, as by being stretched, and then freed, it will perform vibrations which are isochronous, and, as to period, in the main, dependent upon the rigidity of the spring, and its own inertia or that of the system of which it may form an immediate part. This is known to be true in all cases where the force which tends to bring the spring or movable system into a given position is proportionate to the displacement.

In the construction of the engine above referred to this principle is followed, that is to say, a cylinder and a piston are used one or both of which in any suitable manner are maintained in reciprocation by steam or gas under pressure. To the moving piston or to the cylinder in case the latter reciprocate and the piston remain stationary, a spring is connected so as to be maintained in vibration thereby, and whatever may be the inertia of the piston or of the moving system and the rigidity of the spring relatively to each other, provided the practical limits within which the law holds true that the forces which tend to bring the moving system to a given position are proportionate to the displacement, are not exceeded, the impulses of the power impelled piston and the natural vibrations of the spring will always correspond in direction and coincide in time.

In the case of the engine referred to, the parts are so arranged that the movement of the piston within the cylinder in either direction ceases when the force tending to impel it and the momentum which it has acquired are counterbalanced by the increasing pressure of the steam or compressed air in that end of the cylinder towards which it is moving, and as in its movement the piston has shut off, at a given point, the pressure that impelled it and established the pressure that tends to return it, it is then impelled in the opposite direction, and this action is continued as long as the requisite pressure is applied. The length of the stroke will vary with the pressure, but the rate or period of reciprocation is no more dependent upon the pressure applied to drive the piston, than would be the period of oscillation of, a pendulum permanently maintained in vibration, upon the force which periodically impels it, the effect of variations in such force being merely to produce corresponding variations in the length of stroke or amplitude of vibration respectively.

In practice I have found that the best results are secured by the employment of an air spring, that is, a body of confined air or gas which is compressed and rarefied by the movements of the piston, and in order to secure a spring of constant rigidity I prefer to employ a separate chamber or cylinder containing air at the normal atmospheric pressure, although it might be at any other pressure, and in which works a plunger connected with or carried by the piston rod. The main reason why no engine heretofore has been capable of producing results of this nature is that it has been customary to connect with the reciprocating parts a heavy flywheel or some equivalent rotary system of relatively very great inertia, or in other cases where no rotary system was employed, as in certain reciprocating engines or tools, no regard has been paid to the obtainment of the conditions essential to the end which I have in view, nor would the presence of such conditions in said devices appear to result in any special advantage.

Such an engine as I have described affords a means of accomplishing a result heretofore unattained, the continued production of electric currents of constant period, by imparting the movements of the piston to a core or coil in a magnetic field.

It should be stated, however, that in applying the engine for this purpose certain conditions are encountered which should be taken into consideration in order to satisfactorily secure the desired result. When a conductor is moved in a magnetic field and a current caused to circulate therein, the electro-magnetic reaction between it and the field, might disturb the mechanical oscillation to such an extent as to thrown it out of isochronism. This, for instance, might occur when the electromagnet reaction is very great in comparison to the power of the engine, and there is a retardation of the current so that the electro-magnetic reaction might have an effect similar to that which would result from a variation of the tension of the spring but, if the circuit of the generator be so adjusted that the phases of the electromotive force and current coincide in time, that is to say, when the current is not retarded then the generator driven by the engine acts merely as a frictional resistance and will not, as a rule, alter the period of the mechanical vibration, although it may vary its amplitude. This condition may be readily secured by properly proportioning the self-induction and capacity of the circuit including the generator.

I have, however, observed the further fact in connection with the use of such engines as a means for running a generator, that it is advantageous that the period of the engine and the natural period of electrical vibration of the generator should be the same, as in such case the best conditions for electric resonance are established and the possibility of disturbing the period of mechanical vibrations is reduced to a minimum. So much so that I have found that even if the theoretical conditions necessary for maintaining a constant period in the engine itself are not exactly maintained, still the engine and generator combined will vibrate at a constant period. For example, if instead of using in the engine an independent cylinder and plunger as an air spring of practically constant rigidity, I cause the piston to impinge upon air cushions at the ends of its own cylinder, although the rigidity of such cushions or springs might be considerably affected and varied by the variations of pressure within the cylinder, still by combining with such an engine a generator which has a period of its own approximately that of the engine, constant vibration may be maintained even through a considerable range of varying pressure, owing to the controlling action of the electro-magnetic system.

I have even found that under certain conditions the influence of the electro-magnetic system may be made so great as to entirely control the period of the mechanical vibration within wide limits of varying pressure.

This is likely to occur in those instances where the power of the engine while fully capable of maintaining a vibration once started, is not sufficient to change its rate.

So, for sake of illustration, if a pendulum is started in vibration, and a small force applied periodically in the proper direction to maintain it in motion, this force would have no substantial control over the period of the oscillation unless the inertia of the pendulum be small in comparison to the impelling force, and this would be true no matter through what fraction of the period the force may be applied.

In the case under consideration the engine is merely an agent for maintaining the vibration once started, although it will be understood that this does not preclude the performance of useful work which would simply result in a shortening of the stroke.

My invention, therefore, involves the combination of a piston free to reciprocate under the influence of a steam or a gas under pressure and the movable element of an electric generator which is in direct mechanical connection with the piston, and it is, more especially the object of my invention to secure from such combination electric currents of a constant period. In the attainment of this object I have found it is preferable to construct the engine so that it of itself controls the period, but as I have stated before, I may so modify the elements of the combination that the electro-magnetic system may exert a partial or even complete control of the period.

In illustration of the manner in which the invention is carried out I now refer to the accompanying drawings:

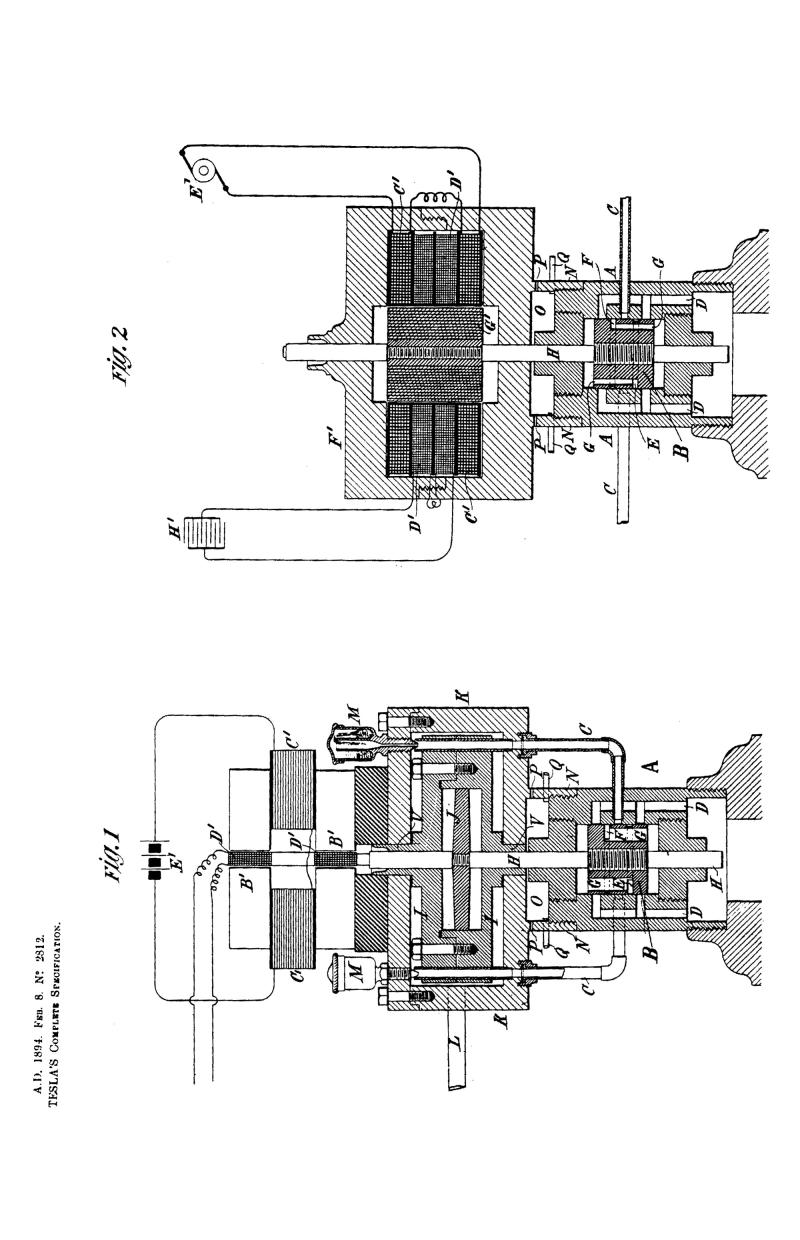

Fig. 1 is a central sectional view of an engine and generator embodying the invention.

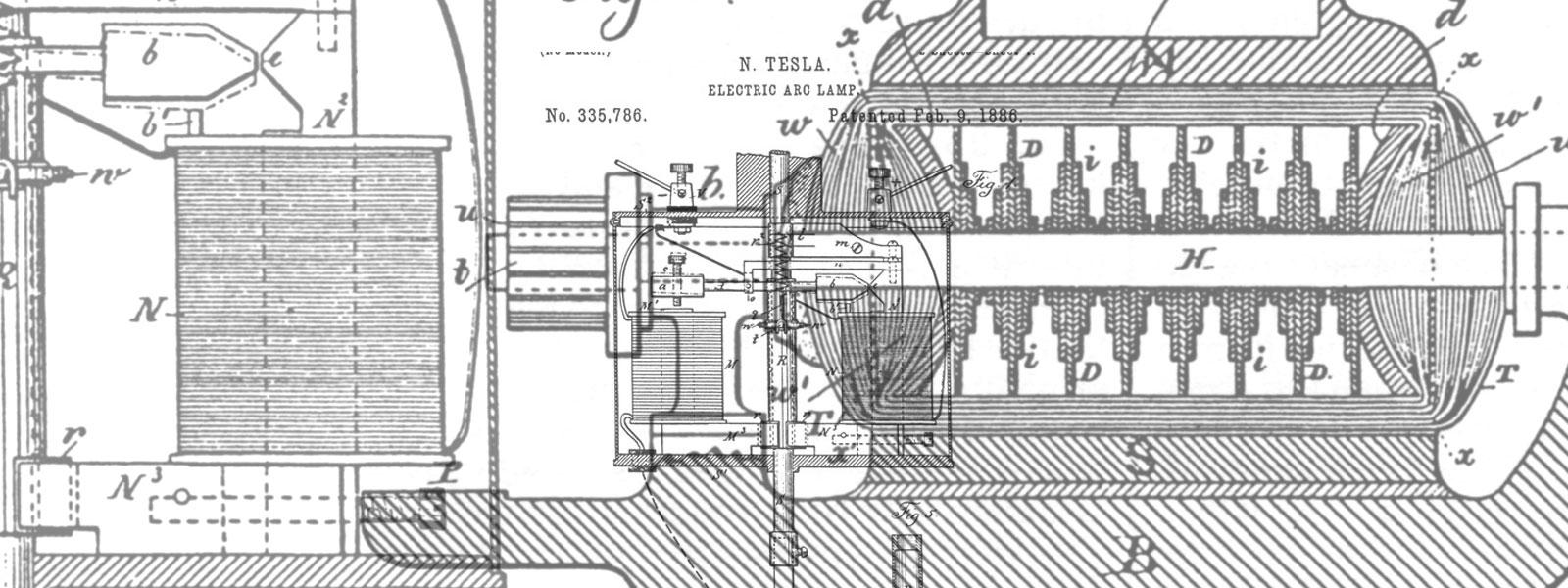

Fig. 2 is a modification of the same.

Referring to Figure 1, A is the main cylinder in which works a piston B. Inlet ports C C pass through the sides of the cylinder opening at the middle portion thereof and on opposite sides.

Exhaust ports D D extend through the walls of the cylinder and are formed with branches that open into the interior of the cylinder on each side of the inlet ports and on opposite sides of the cylinder.

The piston B is formed with two circumferential grooves E F which communicate through openings G in the piston with the cylinder on opposite sides of said piston respectively.

The particular construction of the cylinder, the piston and the valves for controlling it may be very much varied, and it is not in itself material, except that in the special case now under consideration it is desirable that all the ports, and more especially the exhaust ports should be made very much larger than is usually the case so that no force due to the action of the steam or compressed air will tend to retard or affect the return of the piston in either direction.

The piston B is secured to a piston rod H which works in suitable stuffing boxes in the heads of the cylinder A.

This rod is prolonged on one side and extends through bearings V in a cylinder I suitably mounted or supported in line with the first, and within which is a disk or plunger J carried by the rod H.

The cylinder I is without ports of any kind and is air-tight, except as a small leakage may occur through the bearings V, which experience has shown need not be fitted with any very considerable accuracy.

The cylinder I is surrounded by a jacket K which leaves an open space or chamber around it. The bearings V in the cylinder I, extend through the jacket K to the outside air and the chamber between the cylinder and jacket is made steam or air tight as by suitable packing.

The main supply pipe L for steam or compressed air leads into this chamber, and the two pipes that lead to the cylinder A run from the said chamber, oil cups M being conveniently arranged to deliver oil into the said pipes for lubricating the piston.

In the particular form of engine shown, the jacket K which contains the cylinder I is provided with a flange N by which it is screwed to the end of the cylinder A. A small chamber O is thus formed which has air vents P in its sides and drip pipes Q leading out from it through which the oil which collects in it is carried off.

To explain now the operation of the engine described:

In the position of the parts shown, or when the piston is at the middle point of its stroke, the plunger J is at the center of the cylinder I and the air on both sides of the same is at the normal pressure of the outside atmosphere. If a source of steam or compressed air be then connected to the inlet ports C C of the cylinder A and a movement be imparted to the piston as by a sudden blow, the latter is caused to reciprocate in a manner well understood.

The movements of the piston compress and rarefy the air in the cylinder I at opposite ends of the same alternately. A forward stroke compresses the air ahead of the plunger J which acts as a spring to return it, similarly on the back stroke the air is compressed on the opposite side of the plunger J and tends to drive it forward.

The compressions of the air in the cylinder I and the consequent loss of energy due mainly to the imperfect elasticity of the air, give rise to a very considerable amount of heat. This heat I utilize by conducting the steam or compressed air to the engine cylinder through the chamber formed by the jacket surrounding the air-spring cylinder. The heat thus taken up and used to raise the temperature of the steam or air acting upon the piston is availed of to increase the efficiency of the engine.

In any given engine of this kind the normal pressure will produce a stroke of determined length, and this will be increased or diminished according to the increase of pressure above or the reduction of pressure below the normal.

In constructing the apparatus proper allowance is made for a variation in the length of stroke by giving to the confining cylinder I of the air spring properly determined dimensions. The greater the pressure upon the piston, the higher will be the degree of compression of the air-spring, and the consequent counteracting force upon the plunger.

The rate or period of reciprocation of the piston however, is mainly determined, as above set forth, by the rigidity of the air spring and the inertia of the moving system, and any period of oscillation within very wide limits may be secured by properly proportioning these factors, as by varying the dimensions of the air chamber which is equivalent to varying the rigidity of the spring, or by adjusting the weight of the moving parts.

These conditions are all readily determinable, and an engine constructed as herein described may be made to follow the principle of operation above stated and maintain a perfectly uniform period through very wide limits of pressure.

The pressure of the air confined in the cylinder when the plunger I is in its central position will always be practically that of the surrounding atmosphere, for while the cylinder is so constructed as not to permit such sudden escape of air as to sensibly impair or modify the action of the air spring there will still be a slow leakage of the air into or out of it around the piston rod according to the pressure therein, so that the pressure of the air on opposite sides of the plunger will always tend to remain at that of the outside atmosphere.

To the piston rod H is secured a conductor or coil of wire D1 which by the movements of the piston is oscillated in the magnetic field produced by two magnets B1 B1 which may be permanent magnets or energized by coils C1 C1 connected with a source of continued currents E1. The movement of the coil D1 across the lines of force established by the magnets gives rise to alternating currents in the coil. These currents, if the period of mechanical oscillation be constant will be of constant period, and may be utilized for any purpose desired.

In the case under consideration it is assumed as a necessary condition that the inertia of the movable element of the generator and the electro-magnetic reaction which it exerts will not be of such character as to materially disturb the action of the engine.

Fig. 2 is an example of a combination in which the engine is not of itself capable of determining entirely the period of oscillation, but in which the generator contributes to this end. In this figure the engine is the same as in Fig. 1. The exterior air spring is however omitted and the air space at the ends of the cylinder A relied on for accomplishing the same purpose. As the pressure in these spaces is liable to variations from variations in the steam or gas used in impelling the piston they might affect the period of oscillation, and the conditions are not as stable and certain as in the case of an engine constructed as in Fig. 1. But if the natural period of vibration of the electric system be made to approximately accord with the average period of the engine, such tendencies to variation are very largely overcome and the engine will preserve its period even through a considerable range of variations of pressure.

The generator in this case is composed of a magnetic casing F1 in which a laminated core G1 secured to the piston rod H is caused to vibrate. Surrounding the plunger are two exciting coils C1 C1, and one or more induced coils D1 D1.

The coils C1 C1 are connected with a generator of continuous currents E1 and are wound to produce consequent poles in the core G1. Any movement of the latter will therefore shift the lines of force through coils D1 D1 and produce currents therein.

In the circuit of coils D1 is shown a condenser H1. It need only be said that by the use of a proper condenser the self-induction of this circuit may be neutralized. Such a circuit will have a certain natural period of vibration, that is to say that when the electricity therein is disturbed in any way an electrical vibration of a certain period takes place, and as this depends upon the capacity and self-induction, such period may be varied to approximately accord with the period of the engine.

In case the power of the engine be comparatively small as when the pressure is applied through a very small fraction of the total stroke, the electrical vibration will tend to control the period, and it is clear that if the character of such vibration be not very widely different from the average period of vibration of the engine under ordinary working conditions that such control may be entirely adequate to produce the desired results.

It is evident that when a conductor in a magnetic field or a magnetic core, is vibrated by mechanism such as is here described the character of the current impulses developed will vary according to existing conditions, as for example, the current impulses may lag behind the electro motive impulses more or less, and from this it may result that the positive and negative impulses in certain cases may differ in electro-motive force, or the degree of saturation of the core may modify the character of the currents. Thus it is possible in such apparatus, as I have described, to secure a preponderance of the electro-motive impulses of one direction over those in the other, and by a proper observance of these conditions I am able to produce effects similar to those produced by unidirectional currents.

Having now particularly described and ascertained the nature of my said invention, and in what manner the same is to be performed, I declare that what I claim is:

- The combination with the piston or equivalent element of an engine which is free to reciprocate under the action thereon of steam or a gas under pressure, of the moving conductor or element of an electric generator in direct mechanical connection therewith.

- The combination with the piston or equivalent element of an engine which is free to reciprocate under the action of steam or a gas under pressure, of the moving conductor or element of an electric generator in direct mechanical connection therewith, the engine and generator being adapted by their relative adjustment with respect to period to produce currents of constant period, as set forth.

- The combination with an engine comprising a piston free to reciprocate under the action of steam or a gas under pressure, and an electric generator composed of field magnets or coils and a core or conductor capable of oscillation in the field produced thereby, the said core or conductor being carried by the piston rod of the engine as set forth.

- The combination with an engine operated by steam or a gas under pressure and having a constant period of reciprocation, of an electric generator, the moving conductor or element of which is connected with the engine, the generator and its circuit being so related to the engine as not to disturb its period as set forth.

- The combination with a cylinder and a piston reciprocated by steam or a gas under pressure of a spring maintained in vibration by the movement of the piston, and an electric generator, the movable conductor or element of which is connected with the piston, these elements being constructed and adapted in the manner set forth for producing a current of constant period.

- The method of producing electric currents of constant period herein described which consists in imparting the oscillations of an engine to the moving element of an electric generator and regulating the period of mechanical oscillation by an adjustment of the reaction of the electric generator, as herein set forth.

Dated the 16th day of January 1894.

Nikola Tesla.

Haseltine, Lake & Co.,

45, Southampton Buildings, London, Agents for the Applicant.