Nikola Tesla Articles

Exhibit of Tesla's Polyphase System at the World's Fair

By C. F. SCOTT.

An exhibition of power transmission at the World's Fair which is of exceptional interest, is the Tesla polyphase system which constitutes a part of the exhibit of the Westinghouse Electric & Manufacturing company in electricity building. The exhibit includes generators, motors, transformers and other apparatus of various sizes and types. The system itself is not new in its general plan. There are but few features of novelty in the electrical system which have not been the subjects of publications or patents. The purpose of the exhibit is not so much to bring out what is novel in electrical invention as it is to give a complete exhibit of commercial machinery constituting the elements of a power system on a large scale. The exhibit will attract practical electrical engineers rather than those who are interested only in electrical inventions.

The purpose of the exhibit is therefore to show a complete working system for generating, transmitting and distributing power on a large commercial scale. The system includes:

1. A prime mover.

2. A generating dynamo.

3. Raising converters and transmission line and reducing converters.

4. Motors and rotary transformers for general power and electrical service.

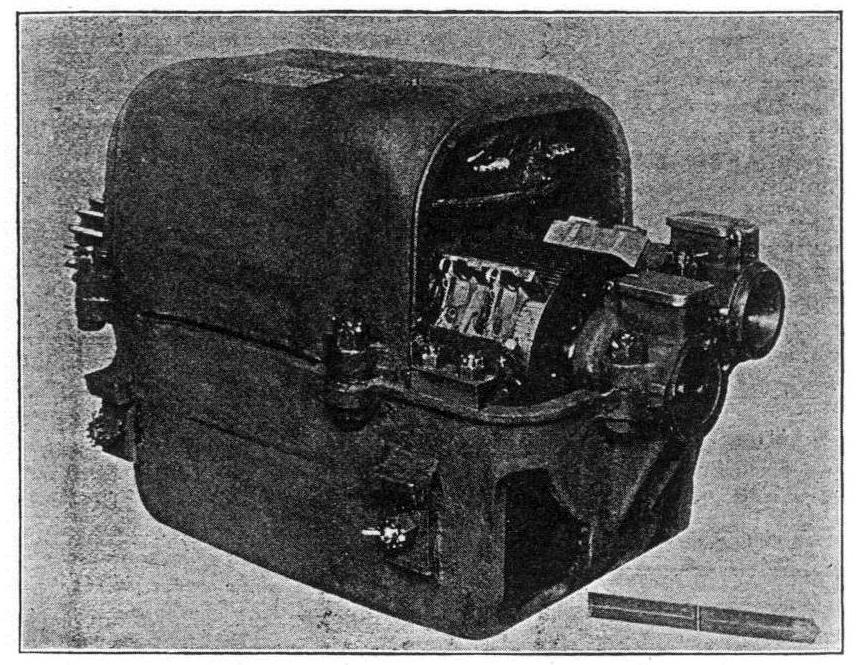

The prime mover in general practice is water power, but in the present plant a 500-horse power two-phase Tesla motor of the rotary field type serves as prime mover. The current for this motor is received from one of the 750 kilowatt, two-phase Westinghouse generators of the lighting plant in machinery hall. The number of alternations is 7,200, and the pressure is reduced from 2,000 to 200 volts before being delivered to the motor. The current is delivered to the rotating element of the motor through brushes resting on four collecting rings. The winding is a drum winding laid in small slots in the surface. The stationary element of the motor is of laminated iron, set in an outside casting. Large copper rods are run through holes in the iron plates near the inner surface, and are suitably connected at the ends. Resistances are put in circuit with this winding for starting the motor, and when speed is attained, these resistances are short circuited, leaving this winding completely closed on itself.

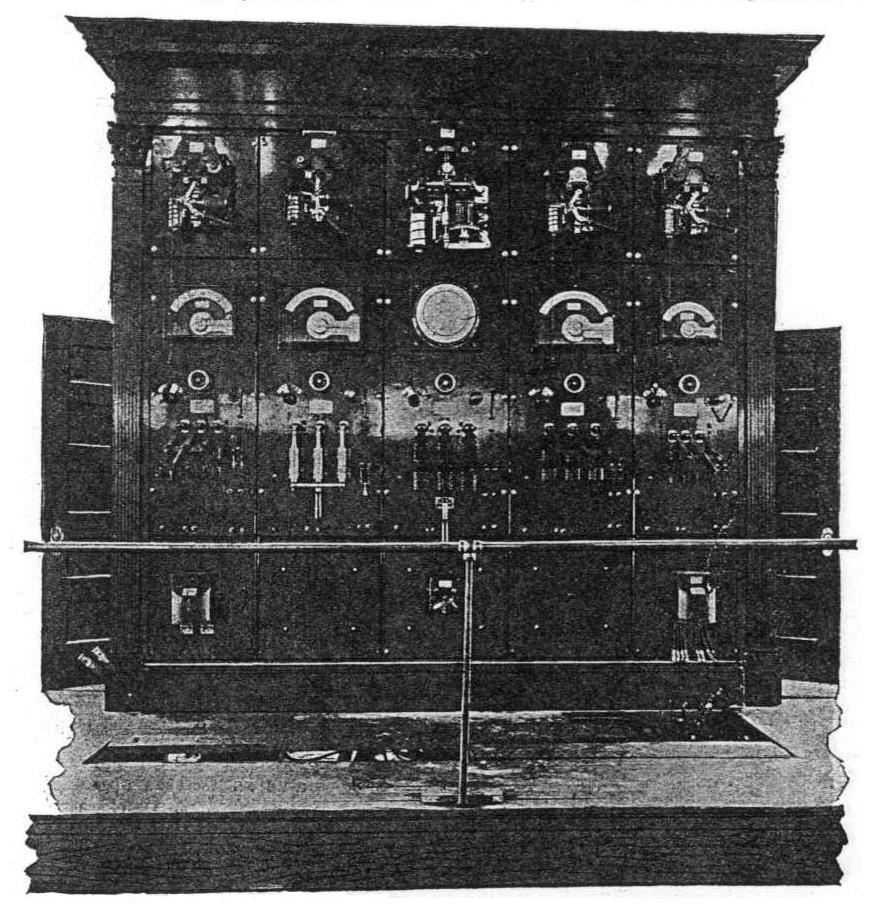

This motor drives a 500 horse power two-phase alternating current generator. This machine is of the ordinary type of railway generator. There is a field of six poles which is excited by a small direct current machine driven by a 5 horse power two phase Tesla motor of the rotary field type. The exciter in general practice would be driven by a water wheel. The large generator delivers from four collecting rings two currents differing in phase ninety degrees. The number of alternations is about 4000 per minute, or 33 1-3 periods per second at a potential of 360 volts on each circuit. The machine is also provided with a direct current commutator connected with the same winding, delivering current at 500 volts. This commutator would not be used when the machine is intended as an alternating current generator only. The current from this machine is delivered to a marble switch-board where it is regulated and connected with the various transmission circuits, as desired. This board will afford facilities for connecting various circuits with any one of the several generators which may be placed in a large generating station. The current from the switch-board is received by alternate current convertors or transformers, by which the potential is raised in the present plant to 1200 volts. In practice, the transformation would be to a much higher voltage, depending upon the distance of trans- mission. The transmission circuit conveys the current to the receiving station, where it is reduced by transformers to electromotive forces appropriate to the machines to be supplied. The current passes through a marble switch-board in which there are suitable provisions for operating the various machines in the receiving station.

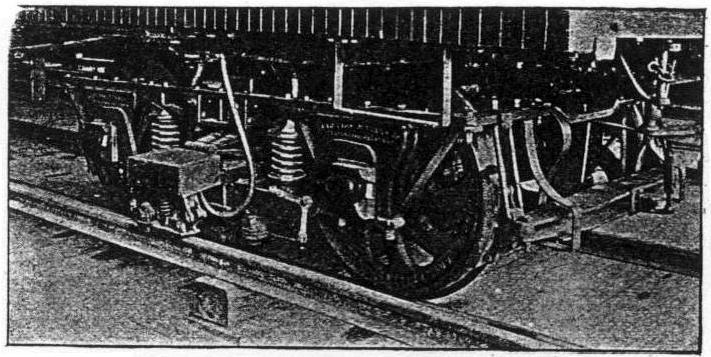

The largest machine in this station is a 500 horse-power is two-phase Tesla motor and rotary transformer. This machine is similar in general construction to the generator described. The alternating current at 360 volts is passed into four collecting rings on the armature. Special connections of the field circuit are made for starting the machine, and when the motor has attained full speed, a switch is turned giving the final connections and running the machine at a self-exciting synchronous motor, which maintains the exact speed of the generator by which it is driven, except in cases of extreme overload. The armature of this machine is provided with a double pulley with belts driving a Worthington pump and a 40-light Westinghouse alternating current arc light dynamo. The armature is supplied with a direct current commutator connected with the same winding which receives the alternating current, and delivers direct current at a potential of 500 volts. This current is utilized for operating two 30 horse power street railway motors mounted upon a standard Dorner & Dutton truck, and also a 60 horse power direct current motor mounted upon an Ingersoll-Sergeant air compressor. This direct current also supplies a series of direct current constant potential arc lamps. The current from the switchboard is also carried directly to a 60 horse power two phase motor and rotary transformer, which receives the current at 26 volts and delivers direct current at 50 volts adapted to electrolytic work, charging of storage batteries, and is at present used for operating the large Schuckert search light in an adjoining space. The current from the switchboard also operates a 60 horse power two-phase Tesla motor of the synchronous type, which is adapted for any kind of constant speed work. In the present exhibit, it is direct coupled to a 45 kilowatt slow speed alternator of the constant potential type used for incandescent lighting. Current from the switchboard is also directly utilized for supplying incandescent lamps.

It is commonly recognized that the mechanical design and workmanship upon electrical apparatus has fully as important a bearing upon its successful operation as the electrical design. In fact, in actual experience it is found that electrical enterprises which have failed or have been unsuccessful have been deficient usually in mechanical rather in electrical elements. It is, therefore, of especial importance to note the mechanical features of a new system, and to observe whether simplicity and strength and durability are insured. Visitors to the present exhibit are struck with the general similarity in construction of the machines employed for widely different electrical purposes. The general form and construction of the large Tesla motor of the rotating field type, the alternate current generator, the alternate current motors, the rotary transformers, the alternating current arc machine and the constant potential alternator have an appearance of general similarity.

The main castings are two in number. The lower one contains half of the field magnets and the bearings for the armature shaft. This simple form insures rigid bearings for the armature. The upper casting contains the remaining field magnets. The field magnets are made of laminated soft steel plates of high permeability, which are cast into the yoke of the machine. The armature is built up of thin disks of soft steel with grooves in the surface for receiving the windings. The armatures are drum wound with, in general, large conductors placed in special heavy insulating tubes through the slots. This construction affords excellent insulation and protection of the wires, and the strains upon the wires, which in case of sudden heavy loads or short circuits may be very great, are transmitted directly to the iron core without chance for slipping or abrasion. In general, no band wires are required. The winding and connection of the armature of the multipolar machines for delivering direct current are such that there are always two and only two parts of the winding in multiple. This insures electrical symmetry, which prevents the improper distribution of current in the armature conductors, which would result if there were a greater number of armature circuits in multiple and the armature should get slightly out of center from excessive wear in the bearings, or other cause.

Attention is called to these points of simplicity and solidity of construction because they are so vital to the success of electrical working, and because the general improvement which is constantly being made in the mechanical development of electrical apparatus has been fully utilized in the design of this system. It is much to the credit of the system, and confidence in its success is assured, for the very reason that it uses and makes but slight modification in types of machines which have been worked out in practice in other lines of service.

This system possesses characteristics which adapt it to a wide field of service, as it combines the requisites for transmitting power over long distances and for transforming it into suitable forms for distribution and application to a wide range of uses. The employment of the alternate current transformer permits the use of low potential machines securing greater cheapness, efficiency and a higher factor of safety than is possible with high potential machines. By the use of alternating current the difficulties in construction and operation, which are inherent to commutators, are avoided on generators and motors. The low pressure of the machine is readily transformed to potentials adapted to great distances. The alternating current supplies two-phase motors of either the rotary field non-synchronous type or of the synchronous type, and the rotary transformer transforms alternating into direct current. The work of this machine is equivalent to that of an alternating current motor driving a direct current generator. The two armatures, however, have been combined in one and placed in one field, and not only is the second machine eliminated but the output of the single machine is greater than that of the two machines together, and the efficiency is increased and the commutation of a greater current is readily effected. The alternating current circuit can supply, therefore, constant potential direct current at any voltage, and is available for all kinds of work in which direct current is necessary or is preferable to alternating current. Incandescent lighting may be supplied from the alternating current circuits, and arc lamps may be supplied by direct current from the rotary transformer or from arc machines driven by synchronous motors.

It should be noted that the idea of complication may result from the grouping of several applications of the system with the transmission system proper. The transmission system proper ends with the switchboard and rotary transformer in the receiving station. Other apparatus would be located where it may be required for use, distributed over a city or through mills and mines.

The alternating and direct current at various potentials for these various lines of service are secured from one generator and one transmission line. This is of practical importance, both in small plants where it would be impracticable to install different generators and circuits for different kinds of service, and also in large plants where there are numerous generators. In such plants similarity and interchangeability of machines and circuits is of great economy and value in practical service.

Electrical inventors have done their part well in discovering the principles and laws which form the basis for a complete electrical system. Designers and mechanics have taken up these inventions and have developed them and constructed apparatus for practical working which is now presented to the electrical engineer for adaptation to the various demands for the transmission and distribution of power. He may take up the work with full assurance, as plants are already in operation which place beyond question the practicability not only of general distribution and service, but also of transmission over long distances and at high potentials, The successful installation and operation of a lighting plant for over 100 horse power using 10,000 volts over a 28-mile circuit in southern California is an initial step which covers a distance greater than is required in a majority of the cases in which power transmission is proposed.

This exhibit of the Tesla polyphase system is the mechanical realization of one of the most unique and beautiful discoveries in electricity in recent years.

* Read before the World's Electrical Congress, August 24, 1893.