Nikola Tesla Articles

Tesla and Schauberger Based Technologies

A Growing Need...

The world's appetite for affordable energy continues to grow. Advanced economies can afford to impose strict environmental standards and either pay to import a substantial portion of their clean energy requirements or use technology to clean their indigenous energy resources. However, economic growth in developing countries is often powered by fuels produced using readily available, low-quality, indigenous energy resources (e.g., subbituminous coal, brown coal, lignite, peat, wood waste). As the quality of the world's environment becomes an increasing concern, there is international pressure to implement stringent environmental standards worldwide. This will require new technologies and processes that will upgrade low-grade energy resources to efficient, clean-burning fuels.

There is a vast market potential for technologies that convert low-quality energy resources to high-quality energy products. In order to meet the requirements of the United States Clean Air Act of 1990 within the next 10 years, there will be a 100 to 150 million ton per year market for compliance coal in the United States that serves power generation and industrial facilities where emissions are not scrubbed. This market is equally impressive abroad; total world coal consumption in 2010 is forecast at 7.5 billion tons per year, 80 percent of which will be used outside the United States. Additionally, the world market for renewable resource fuels (e.g., bagasse, biomass, municipal solid waste, sludge, wood waste) is rapidly expanding as users recognize that renewables have significant benefits that can result in long-term lower cost service, less environmental degradation, and reduced risks.

Early Endeavors

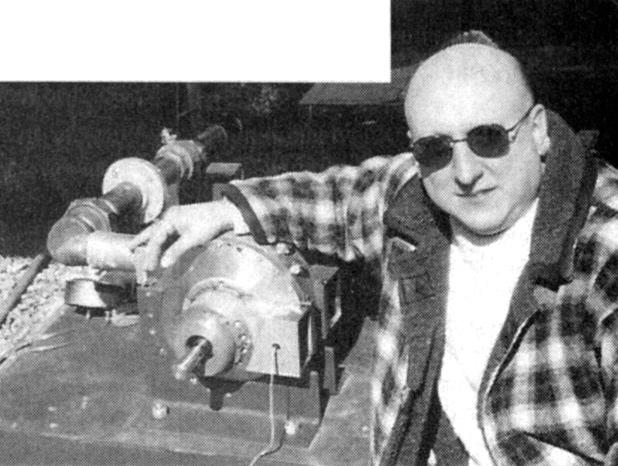

International Turbine And Power, LLC was founded by myself and a group of highly energetic engineers and scientists in 1998. We had only one goal; design a working Tesla Turbine and Tesla Pump. This goal became reality. During the 2000, 2001 and 2002, several functional prototype turbines were designed, built and tested, with each yielding remarkable performance results. Individual investors and investment companies provided the necessary funding of several million dollars for this research and development stage. In 2004, ITP entity was dissolved.

My efforts have continued with a newly formed company, "Global Energy Technologies" (also referred to as GET, Inc). GET has continued production of these revolutionary power and pumping systems based on the pioneering research originally begun by Nikola Tesla, and of which he patented in 1911. Our prototype turbines have confirmed Tesla's claims, and, in our opinion (and third-party testing and validations), these turbines have become the "most simple rotary engines" yet designed. We have improved on Tesla's original design by further incorporating the vortex and implosion designs pioneered by yet another of history's forgotten figures, namely - Viktor Schauberger.

Functional Tesla-type Turbines

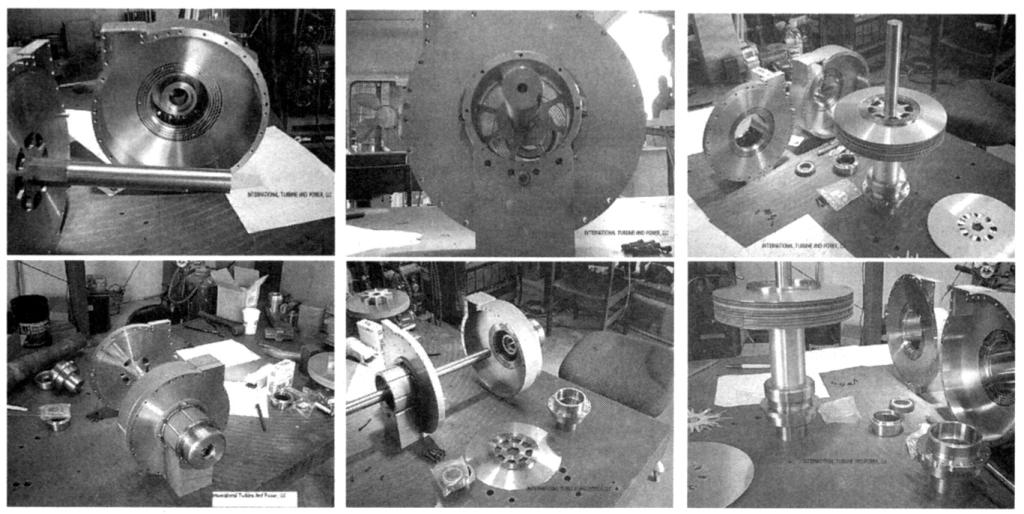

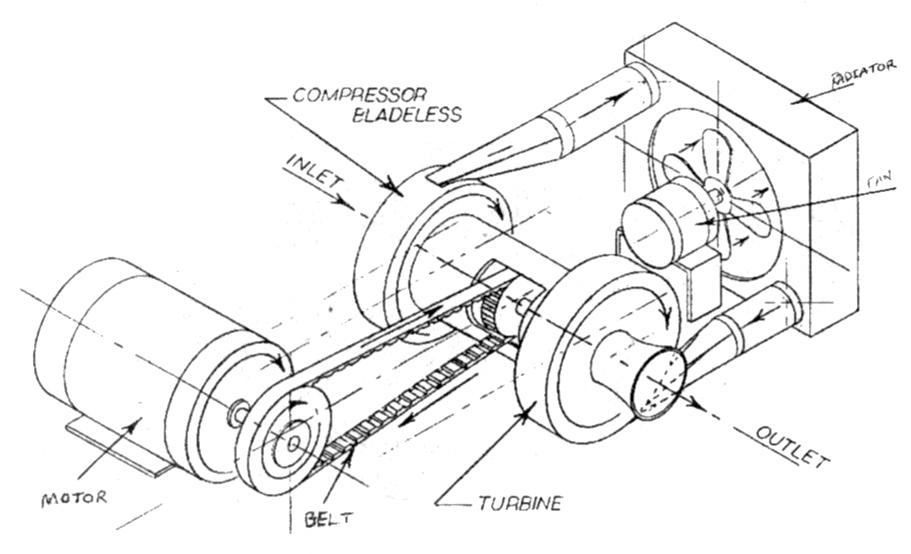

The pictured Tesla-type turbine and the pictures of its assembly components depict our "third-generation" designs. This bladeless disc Tesla-type turbine can be run on combustion (propane, methane, hydrogen, etc.) steam, water powered, or from compressed air. Tests have been run from combustion, steam, compressed air and water. To date, the turbine has been fully operational since October of 2000, running without any component failure.

This bladeless disc turbine features 304 stainless steel construction, throughout, magnetic shaft seals, ceramic high-speed bearings, and a stainless steel casing. Total weight of the unit is 104 pounds, including mounting and combustor. A variable inlet geometry is used allowing true multifuel operation. Maximum rated RPM is 18,000. Total maximum HP is approximately 130 SHP. Disc diameter is 10" with 29 primary active discs, plus two tapered end discs. Static labyrinth seals are used for internal case-to-rotor exhaust sealing.

ITP's BETA, CHARLIE, and early DELTA series turbines were fully functional units. The photos on the opposite page illustrate the simplicity of design of our turbines. They also show the high quality and workmanship that went into the construction of these turbines. No other company to date has built as many successful, fully operational Tesla Turbines as Frank Germano and International Turbine And Power. The corporate entity of International Turbine and Power, LLC has ceased operations, effective as of August 2003.

Bladeless Tesla Steam Turbine

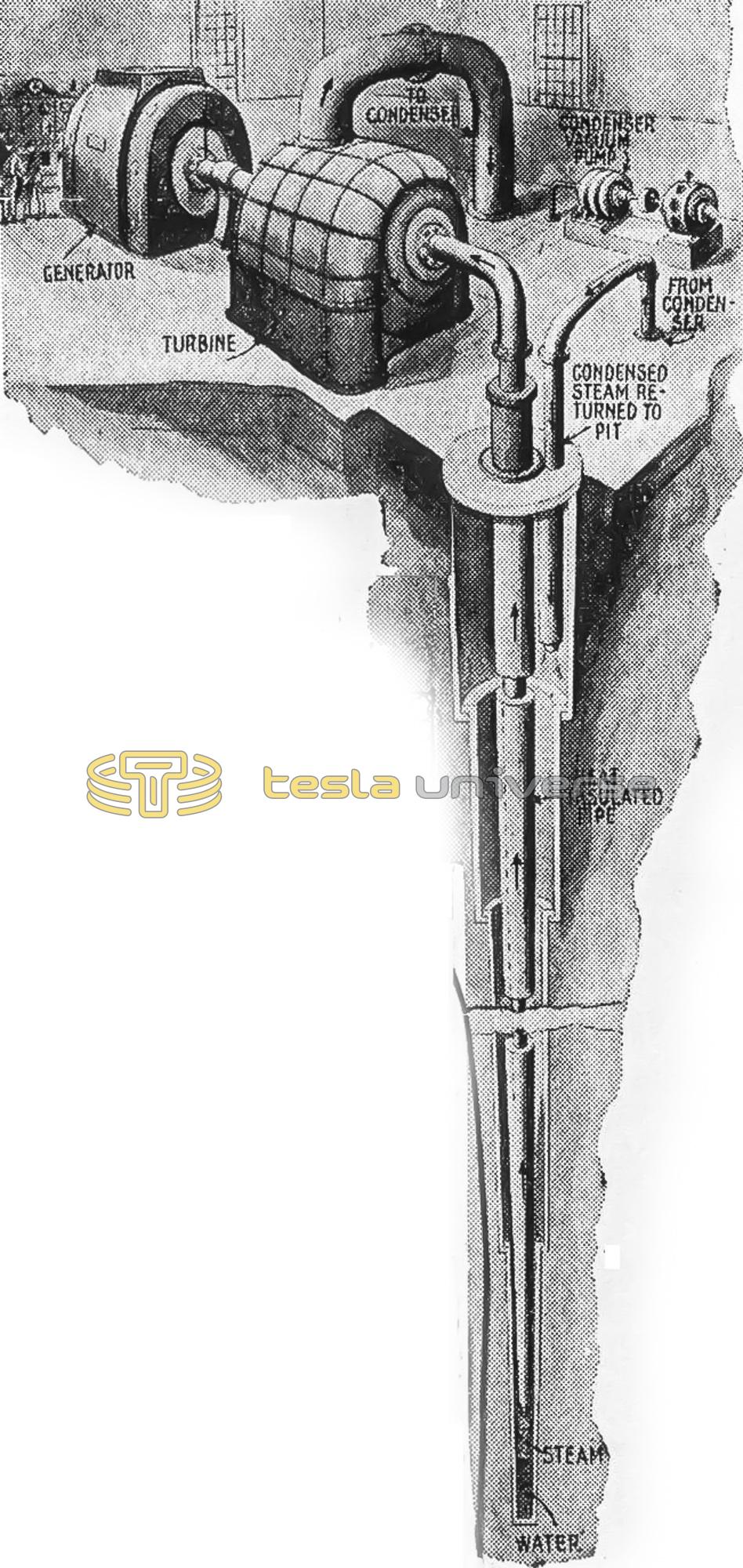

The bladeless disc turbine, powered by steam, generated from a solar intensifying system, is an answer to "free" energy... Steam drives the bladeless disc turbine, which runs a generator, supplying electricity... a Tesla-type pump recirculates the water supply. The initial cost of the equipment is minimal, owing to the relatively low cost of the units. Also, this is a steam driven system which equates to zero pollution, and it is 100% "off - grid" (no need for the electric or gas companies here!). An added benefit of such a system is the ability to desalinate water, thus, the system, by its very nature, provides clean and pure drinking water.

Almost a quarter of the air pollution today comes from the coal being burned to generate electricity. Fuel consumption, resulting in air pollution and acid rain, could be significantly reduced simply by replacing the conventional blade steam turbines currently used by utilities with the Bladeless Tesla Steam Turbine. This also would have the added bonus of drastically reducing maintenance. But the real solution lies in using low temperature wet steam occurring naturally from the ground in the form of geothermal energy.

This energy would destroy a conventional bladed steam turbine, unless expensive steam drying is employed. However, the Bladeless Tesla Steam Turbine requires no drying and can be connected directly to the geothermal source. It has been estimated that the geothermal potential in just Southern California alone, could power the entire North American continent with NO POLLUTION! Add to this the large geothermal potential of Wyoming (ie. geysers in "Yellowstone Nat'l Park"— that's geothermal energy), Oregon, Washington, Idaho and Montana, and you will begin to get the picture of the enormous geothermal potential available in the Northwestern states alone.

Large oil companies have comprehended the potential of geothermal energy and have purchased many of these large tracts of prime geothermal land. Due to the revolutionary concepts embodied in this engine, we can easily end the so called energy crisis and dramatically reduce pollution. Even the vested energy interests are beginning to understand that now is the time for change, realizing their future health and wealth is directly linked to that of the environment.

The bladeless Tesla Steam Turbine system, when adapted for geothermal heat sources, is quite probably the finest example of clean, nonpolluting "green" power ever made available and offered commercially. The Tesla-type system needs no other alterations to take full advantage of geothermal steam sources. Whether coupled directly to the steam source, or if water is fed down via piping into the earth and the superheated steam returning is used, the Tesla turbine system can take the condensate or the steam directly with no dehydrator connected.

The turbines we have designed and constructed can run through the entire adiabatic cycle (from water condensate to steam to superheated steam and back to water) without any damage to our units. In fact, there are numerous advantages of allowing the turbine to run in a water saturated state. The incredible fact is that there are so many spots on the planet which can provide geothermal steam, that we NEVER even had to use fossil fuels to generate electricity. This system is a totally nonpolluting, sustainable, ecologically sensible electrical energy production solution.

Home Power Generators

With the bladeless disc turbine engine coupled to a generator (50, 75 or 100 KW), your home or small business becomes the utility. After installation, whenever your home's electrical needs fall below the unit's output level, the surplus electricity is SOLD back to the utility company; in essence, they send YOU a check in the mail. The bladeless disc turbine runs on propane or natural gas (where available), or hydrogen gas, diesel, or standard pump gasoline. It utilizes this gas as fuel to provide electricity for power for your house or small business.

The emissions produced are rendered virtually contaminant free, due to our revolutionary combustion process. With electricity being produced on-site, transmission and distribution costs are reduced or eliminated, and both economic and environmental benefits are achieved. As a bonus, surplus power could be sold into the electrical grid, further improving the overall economics, as stated earlier.

In our portable models, you can take your "power" with you, which is great for contractors, or second/vacation homeowners. These units are maintenance free, extremely quiet, efficient, and, with the prices of natural gas and propane (currently), the cost of operation is about one half that of using electricity from the utility grid source. The units can also be used as a backup power generator, if utility grid connection is maintained.

After the events of August 14th and 15th, 2003 and 50 million people in the northeastern United States being left without electricity, we should become seriously aware of our waning electrical utilities ability to provide uninterrupted service.

extracted from

Our Future Motive Power

by Nikola Tesla

Everyday Science and Mechanics

December 1910

In this instructive article, the great scientist and inventor who revolutionized industry and communication with his alternating current motors and distributing system, and opened the way for radio with his high-frequency researches, analyzes the problem of obtaining power to replace our wasted fuel, and indicates the method of tapping the earth's hidden resources which will support the industry of future generations.

Caption: Above and at the right, the arrangement of one of the great terrestrial-heat power plants of the future. Water is circulated to the bottom of the shaft, returning as steam to drive the turbine, and then returned to liquid form in the condenser, in an unending cycle.

Internal heat of the earth is great and, in comparison with the demands which man can make upon it, is practically inexhaustible: since the heated contents of the earth are sextillions of tons.The material as well as intellectual progress of Man is becoming ever more dependent on the natural forces and energies he is putting to his service. While not exactly a true measure of well being and enlightenment, the amount of power used is a reliable indication of the degree of safety, comfort and convenience, without which the human race would be subject to increasing suffering and want and civilization might perish. ...

Victor Schauberger realized that creative centripetal forces actually increases the amount of work that a given amount of water can do. Thus by utilizing these vortexial forces, a hydroelectric dam's output could be dramatically increased, even though the flow is actually lower!

Therefore instead of blocking the waterflow with tremendous (and hazardous) dams, the water only need to be redirected using Schauberger's principles to be harnessed effectively.

With Tesla-type turbine power units installed at your location, your electrical supply is guaranteed. These systems would also allow for "buffering" the utilities companies' lines - the units are designed to sense a potential line volt failure and send additional electricity into the system, thus preventing this situation from happening on a large scale ever again. This goes without saying that enough of our systems have been installed in a given area.

Exotic Fuel Sources

As urban populations grow, the treatment of massive amounts of residential and commercial waste, often referred to as "the biomass" becomes increasingly difficult. Landfill and waste disposal sites generate methane gas through the natural process of biodegeneration. The handling of this low grade gas is a problem to municipalities and it is normally vented to the atmosphere.

The bladeless disc turbine engine can efficiently burn this poor quality methane as fuel and in doing so reduces harm to the air quality as well as producing a revenue source - electricity. One of our first units was fully tested "on-site" in New Jersey, proving our claims. It is entirely feasible and practical to use methane gas from landfills to supply the gas to drive a bladeless disk turbine (Tesla Turbine). Considering the vast amount of refuse (waste) being dumped in the United States, and considering that this waste is usable, it would be a folly to simply let this "free" source of energy go untouched.

With the abundance of landfill locations, and the methane gas that could be captured (the process of natural decay of waste matter), we could quite easily meet our electrical needs simply by installing Tesla Turbines throughout each landfill and use the methane gas to fire high-efficiency combustors. The turbines would drive either DC or AC generators. Power output would range from the lower end of 500 KW to a possible 3 Gigawatts.

Furthermore, it has been recognized for decades that the livestock industry is a major contributor to global bio-waste. Mid and large size operations produce significant amounts of greenhouse gases, mainly from the breakdown of animal manure. This is a waste fuel source that Tesla technology can utilize and return multiple benefits to both the ranchers and the environment. Feedlots and farms consume electricity and are always looking for ways to reduce expenses.

Hydroelectric Power Generation

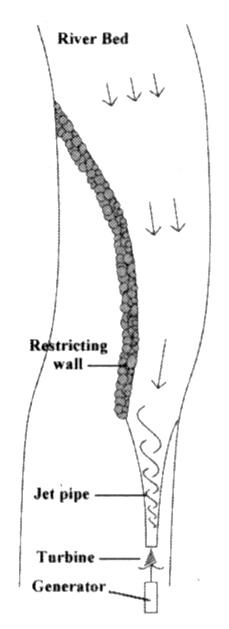

By utilizing the bladeless disc turbine engine, and the bladeless disc turbine Tesla-type Pump with the theories of Victor Schauberger (Vortex theories), we have a truly nonpolluting, free energy source... simply divert the path of a river's flow, accelerate it by using our "InVAID®" technology vortex generator, and "tap" the potential energy of "living water" with the Tesla engine. This system can be built to any commercial size necessary, with an almost limitless power output, dependant only on the available water flow and energy available.

What exactly are we talking about here? Take ANY flowing body of water, ie. large river, anywhere in the United States, or the world in general (for that matter), and, without building any dam or creating any reservoir, we can, through specific design, create a vortex-generating structure in the active water flow (a concrete reinforced structure that aims the water into a specially designed vortex generator— funnel—which will then accelerate the water into a special type of Tesla bladeless disc turbine). No environmental impact, no unsightly dams or reservoirs, no damage to the wildlife, no loss of acreage.

This technology is available NOW. By simply using several of the available rivers in the United States, alone, we could easily supply all of our current electrical needs - all without ANY pollution. Free energy? Not quite; however, it's about as close as we are going to get. Nonpolluting energy derived from an abundant supply of flowing water.

Endless? Yes... as long as the water flows, there will be enormous amounts of power generated. Another application is for supplying usable amounts of electricity to rural areas that would otherwise be considered too costly for utilities to run standard electric lines to.

Refrigeration & Air Conditioning

As an air compressor it is highly efficient. There is a large engine of this type now in practical operation as an air compressor and giving remarkable service. Refrigeration on a scale hitherto never attempted will be practical, through the use of this engine in compressing air, and the manufacture of liquid air commercially is now entirely feasible. - Nikola Tesla, 1911

We could not have stated it better. Through the use of the bladeless disc turbine, coupled to a bladeless disc Tesla-type pump, with a condenser between, we have quite probably one of the most efficient forms of air refrigeration ever invented, and, without the need for harmful, environmentally ‘unfriendly' gasses, Freon or otherwise. This system is also reversible, forming our patent pending "Fresh-Cool®" heating/cooling technology. When adapted to industrial, commercial, or home markets, as a heat-pump system - it is without equal. The electrical energy consumption alone makes it a very attractive alternative to conventional technology.

Without incorporating a compressor stage (which all conventional systems must use), the bladeless disc turbine Tesla-based heat pump can cut more than 3/4 off your present electric bill. This is a conservative estimate. We are currently coordinating efforts to install these air-to-air conditioning systems in several large commercial facilities. As an air compressor, the bladeless disc turbine/pump units are without equal, both in their performance and their cost of operation. As a pumping application, one such pump now in operation, with eight discs, eighteen inches in diameter, pumps four thousand gallons a minute to a height of 360 feet. Try accomplishing that task with a conventional pump of similar size.

As an air blower or fan replacement, the Tesla pump is without equal. It is a simple fact that fans are inherently noisy due to the fan-blade "shearing" through the air, causing violent disruption of the air medium and sound wave emissions.

Bladeless disc systems are inherently quiet, causing no disruption to the airflow other than its rapid movement. In the same space now occupied by a conventional fan (bladed) system, our systems can easily triple or quadruple the amount of air movement. Replacement fans and blower replacements are just a few of the applications where bladeless disc technology would be beneficial.

Industrial & Commercial Air Transport

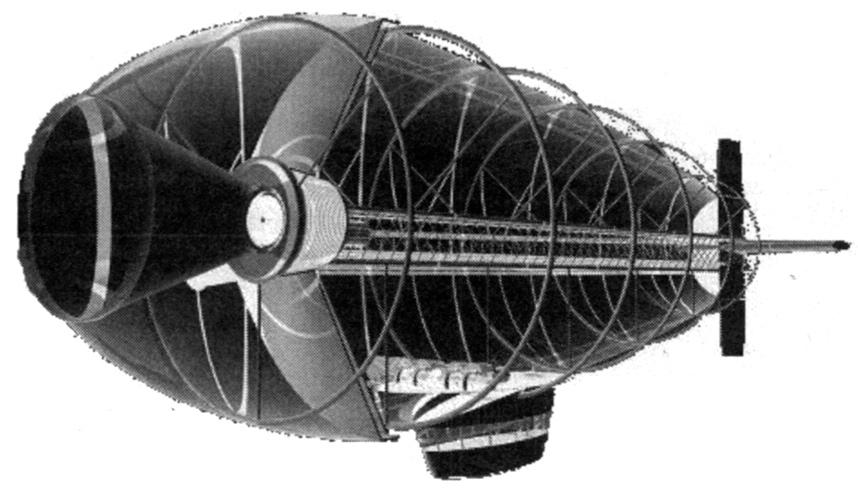

For commercial and industrial aerial transportation of goods and products, I have designed an economical system that incorporates Schauberger and Tesla ideas —we start with a large, helium-filled, aluminum structure; a "blimp" (much larger than the blimps of the recent past). This blimp is shaped in the form of an elongated egg. (see Living Energies by Callum Coats - a detailed description, foundation and history of the theories of Viktor Schauberger for a complete description as to why we chose this shape)

At the frontal section is an intake area opening, which draws in the atmospheric air, which is accelerated via a bladeless disc turbine Tesla-type hybrid system. This super-accelerated and pressurized air is now forced out slits in the forward third sides of the blimp (think of a fish's gills), and the now deoxygenated, pressurized, velocitized air forms vortices along the sides of the blimp, allowing for reduced friction and a "slip" effect as the craft travels through the air. This is an application of our "InVAID®" technology to its fullest. A high degree of mobility is thus afforded, and the craft is capable of lifting an incredible amount of tonnage (products and goods), and traveling at unbelievable speeds approaching 250 knots. Additional outboard pods, fitted with smaller bladeless disc turbine propulsion systems are installed in several locations around the craft offering a high degree of directional control and stability in any weather condition, particularly effective for maneuvering and landing the craft.

Having only done basic, preliminary calculations, this system, when adapted to carry freight (commercial and industrial shipping applications) would drastically cut and lower the cost of shipping products from and to overseas markets. This system is not only more cost effective, in terms of the cost of the shipping, itself - it would also save time (drastically faster than any ship or tanker/carrier; 250 knots vs. 25 knots max with a standard ocean transport ship). It is also immune to changes in weather or ocean storms.

This craft can be designed to carry passengers, and could be outfit for intercontinental luxury air cruises. The craft could also be outfitted to fight forest fires. With the enormous lifting potential of lighter-than-air crafts, the units would be ideally suited to carry water or fire-retarding materials and could easily be maneuvered over large landbased fires and drop their load on target. For personal transportation, imagine going back to the days of yore, and floating silently in the lap of luxury over the continents or the Earth's oceans... blimp travel was once considered to be the most luxurious way to travel - it could be so again. With the abundant supply of relatively cheap helium gas, and the speed afforded by our Tesla-type systems, this could become the wave of the future.

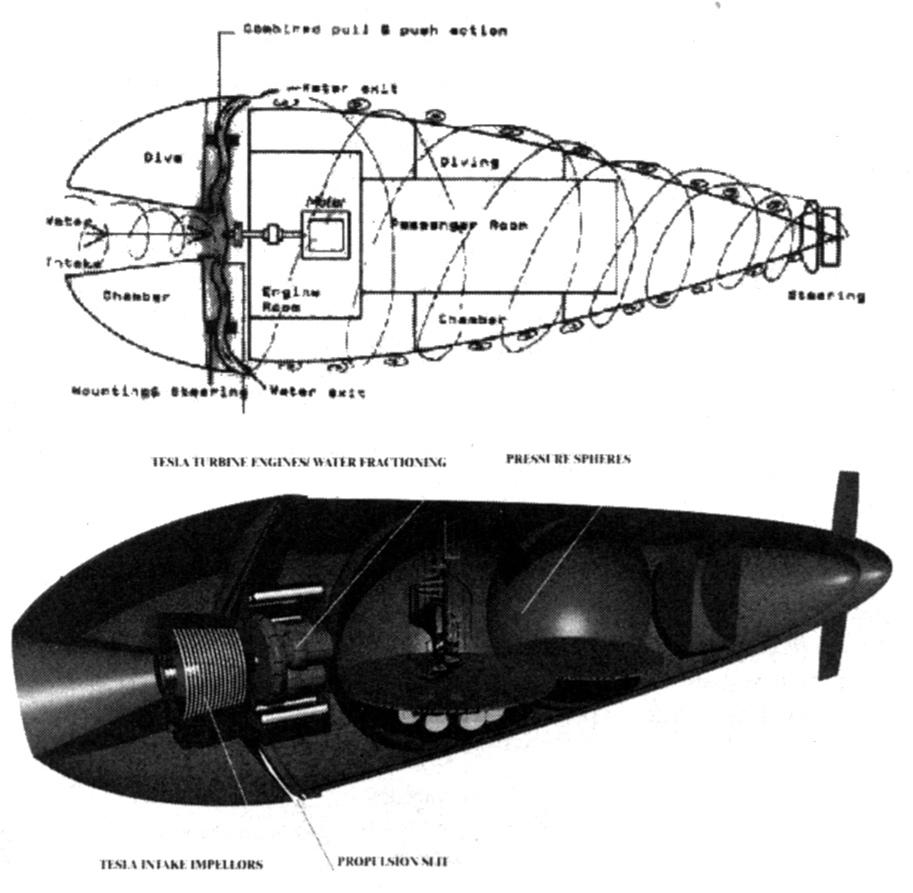

This exact process and design can be utilized in submersibles as well. This creates some unique possibilities in regards to ocean transportation. Since the craft would now operate under the water's surface, it would effectively be mostly immune to weather conditions on the surface. Speed would be greatly increased over a standard ship's ocean surface speeds, as well.

Vertical Lift Aircraft

This system simply replaces the standard rotors on an existing helicopter with our Tesla-type discs. These discs are contained underneath and inside of a specially designed "Frisbee" shaped, lightweight unit. The incredible thrust developed by the Tesla bladeless disc system is redirected by the "Frisbee" shaped shroud, and is forced downward. At the same time, the incoming air from above is sucked so violently into the system that a vacuum is created above the craft, enabling an almost amazing amount of lifting forces to be generated. The advantages of this type of system are obvious -the helicopter with no other modifications than those mentioned above, now has approximately 10 times the lift capacity, and is now capable of almost any forward velocity (dependant on its thrust capability - it can easily go to MACH speeds, if so designed!).

This system will radically alter the way helicopters could be used in the modern warfare arena. The advantage of this type of system is quite obvious vs. conventional bladed technology. Without any further modifications, the new "X-Plane" from Lockheed (or the losing prototype from Boeing) could easily be outfitted with a Tesla-type bladeless disc turbine. What would this do? In relatively the same physical space now occupied by the conventional bladed lift (thrust) impeller, almost five times the lift would be realized by switching to our type of system. Not too bad... if only one of these companies would listen.

Automobile Cooling System Pump

These are four inch diameter water pumps. It is specifically designed to pump cooling water for internal combustion engines of all sizes and types. It has an inch and a quarter inlet and a one inch outlet. It will pump approximately 1,000 gallons of water per hour at 12 PSI. It is driven by a flat pancake type DC motor that is only 1/2" thick. Its power requirement is 100 watts. The pump itself is fabricated from 6061 aluminum, hard anodized, which is equivalent to a type of stainless steel that is capable of going through a 200 hour salt spray test. The bladeless pump can pump boiling water without cavitation without losing its prime.

Conventional pumps cannot pump boiling water, leading to engine damage if the cooling system does reach the boiling point. This will allow a new type of cooling system for automobiles that will replace the belt driven water pump. The electric motor that drives this pump will not operate when the temperature of the engine indicates that it is not required. The pump will only operate when it is needed. The operating temperature can easily be adjusted in the field from 180 degrees to 200 degrees without having to replace a mechanical thermostat as is the normal procedure.

The conventional lifting surface centrifugal pump that is normally used requires from 6 to 10 HP to drive it off a belt. The new bladeless pump will operate only when needed and then consumes less than one HP. Another example of reduction of parasitic horsepower. This pump is currently not available for commercial sale but has been fully tested and awaits investment funding.

Dredging Applications

We can design pumping systems which can handle the most demanding pumping conditions. One such pump now in operation, with eight discs, eighteen inches in diameter, pumps four thousand gallons a minute to a height of 360 feet. Try accomplishing that task with a conventional pump of similar size. Owing to the fact that the bladeless pumps can work effectively pumping virtually any fluid or gas, they can easily be built to any performance level required. One of the most intriguing areas is in dredging applications.

Current dredging technology is woefully ineffective. By using a bladeless disc pump, unbelievable efficiencies with ocean-bottom sand removal and relocation could be attained. The pumps are self-priming, and by the action inherent in the pumps themselves (boundary layer adhesion and viscous drive) minimal contact with the internal discs occurs, thus enabling operation where other pumps would quite simply fail.

For coastal areas, we can design systems that will not only cost less than current dredging operations - our systems will operate without failure, and remove virtually all sediment, sand, aggregate and the like, without clogging, and move it in incredible volume to the site of your choosing.

The Scrap Heap of the Future

Given the advantages of bladeless turbines and pumps, one must wonder why this extraordinary technology has not been universally adopted. A good portion of the answer lies in this short passage related by Nikola Tesla in his autobiography... My Inventions:

Only the other day, I had a disheartening experience when I met my friend and former assistant, Charles F. Scott, now professor of Electric Engineering at Yale. I had not seen him for a long time and was glad to have an opportunity for a little chat at my office. Our conversation, naturally enough, drifted on my turbine and I became heated to a high degree.

"Scott, " I exclaimed, carried away by the vision of a glorious future, "My turbine will scrap all the heat engines in the world. "

Scott stroked his chin and looked away thoughtfully, as though making a mental calculation. "That will make quite a pile of scrap," he said, and left without another word.

Viktor Schauberger, born in 1885, set a modern precedent in the understanding of the nature of water. His insights came from observing natural phenomena such as the undulation of the water snake and the meandering nature of water. His understanding of cycloid spiral motion led him to develop technology complementing Tesla's turbine and pump technology. Viktor Schauberger's central theme was:

Prevailing technology uses the wrong forms of motion. Our machines and processes channel such agents as air, water and other liquids and gases into the type of motion which Nature only uses to decompose and dissolve matter. Nature uses another form of motion for rebuilding. When our technology only uses the decomposing motion, it becomes a dead technology, a destructive one, dangerously affecting all of Nature.

However, Schauberger, like Tesla, never saw his technology achieve its full potential. Apparently the "powers that be" chose to extend the life of their inefficient technologies rather than upset the status quo by retooling their industries. They chose economics over the environment. Now, the past is meeting the future!

Applications of Tesla and Schauberger technology could be implemented with very little investment monies. All technologies presented are systems that this author has previously worked on in depth with others. All of the applications highlighted in this article are "Earth-Friendly", and present an enormous advance in pollution free power generation.

At this juncture, interested investors are encouraged to contact me for more information concerning Global Energy Technologies, Inc and our capabilities--contact information is at the head of this article. We can provide the technology; we only await the necessary funding from investors that are farsighted enough to realize the implications of what will happen if we DON'T do something soon. Help build the scrap heaps of tomorrow!