Nikola Tesla News

Restoring Sparks: Tesla Coil Repair at Roper Mountain Science Center

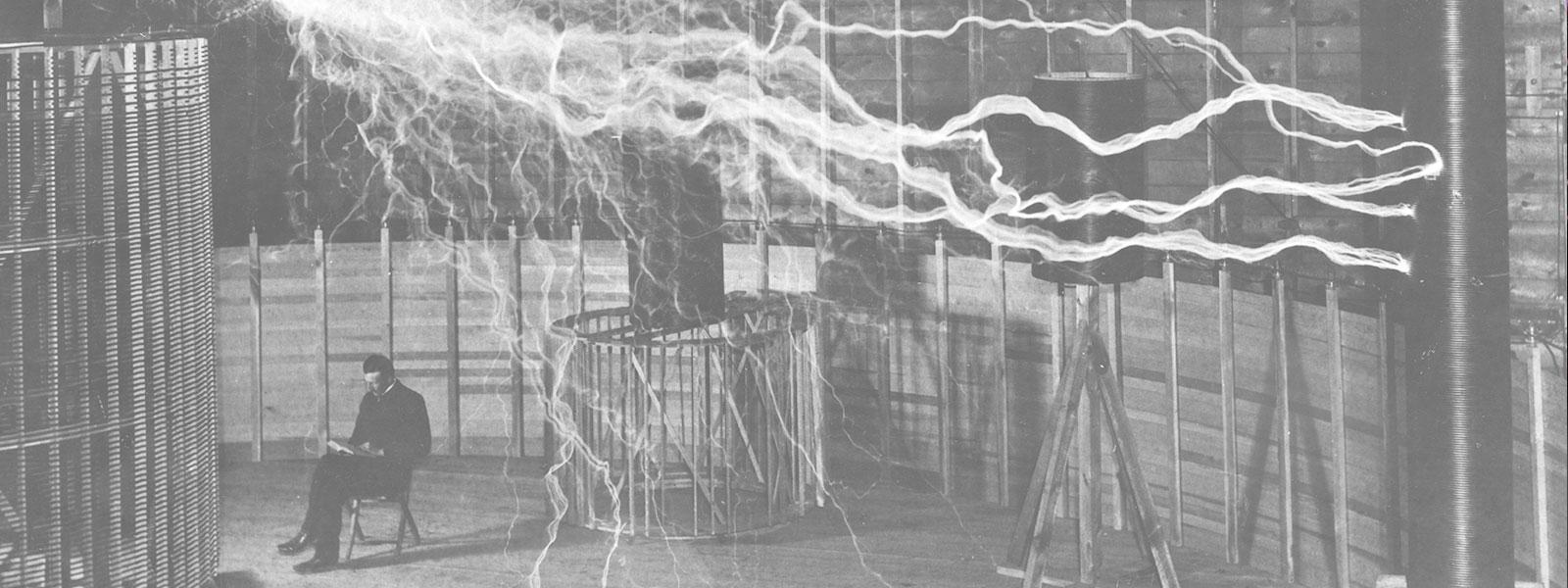

We were recently contacted by friendly folks at the Roper Mountain Science Center in Greenville, South Carolina. Their science museum houses an impressively large Tesla coil built by the late Robert Iannini, founder of the now-defunct Information Unlimited.

The museum had been shut down during the pandemic, and staff turnover had disrupted operations. We were hired to inspect the Tesla coil and train new staff to resume the exhibit.

The connecting flight took as long as driving from Huntsville, but I flew to catch up on project work.

Upon arriving, I was struck by the coil's size. I had worked on Information Unlimited Tesla coils before, but none nearly this large. Standing over six feet, it was driven by three 15kV/60mA Franceformer neon sign transformers (NSTs) in parallel, giving it significant power.

However, I was less impressed by the rat's nest of cables. The theater hosting the coil doubled as an A/V space, and the tangled wires included RGB, audio, and Tesla coil cables. In other words, it was a recipe for disaster, especially with a spark gap Tesla coil, a component prone to electrical interference.

I unraveled the wires and checked each with a volt-ohm meter (VOM). I inspected the power cabinet connections, adjusted the spark gap, replaced frayed terminals, and the coil was in good shape. The controller, built into the power cabinet, consisted of a contactor and a low-voltage supply. A key switch was in series with a phono jack connected to a handheld push-button switch on a long cable.

When I tested the Tesla coil, nothing happened. A more thorough examination revealed a cracked jack, and the contactor would fire only if I applied pressure to the plug in a specific way.

With Radio Shack stores gone, a 1/8-inch phono jack is difficult to find locally. After conferring with the museum staff, we agreed they were comfortable hardwiring the switch to bypass the plug and broken jack.

After some soldering, the switch worked reliably. I cleaned the secondary and toroid, checked the primary connections and capacitors, verified the ground connection, and was ready to test.

It was the moment of truth! I slowly brought up the variac (variable transformer) and heard the familiar crackle. A smile spread across my face as I increased the voltage, and the sparks grew. At about 70%, the sparks stretched over four feet, striking the chalkboard frame on the wall behind the coil. It was glorious.

The staff heard the ruckus and rushed in. Some remembered the sound, while it was new to others. Their awe was palpable.

I spent the remainder of my time providing training, discussing safety, and emphasizing cable management.

Though I never met Bob Iannini, I still have my first Information Unlimited catalog from the 1980s. I've ordered from them many times over the years. Bob's Tesla coil-related articles in magazines like Radio Electronics inspired me when I was starting out.

I hope Bob was looking down, smiling, when the sparks from his coil flew again.

Visit the Roper Mountain Science Center at rmsc.org for showtimes. I understand the coil is now operated regularly again.

Thanks to Erin and Joe for their hospitality, and for trusting us to help with their awesome Tesla coil.

Cameron