Nikola Tesla Articles

An Automobile Speedometer That Operates by Air Friction

Depending upon the principle of air friction and consisting essentially of two metal cups fitting one into the other, but not touching at any point, a speedometer has been developed to a commercial stage after three years' experimenting on the part of a leading watch company.

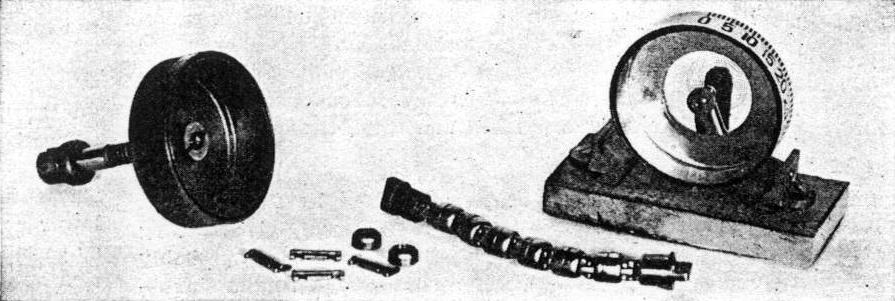

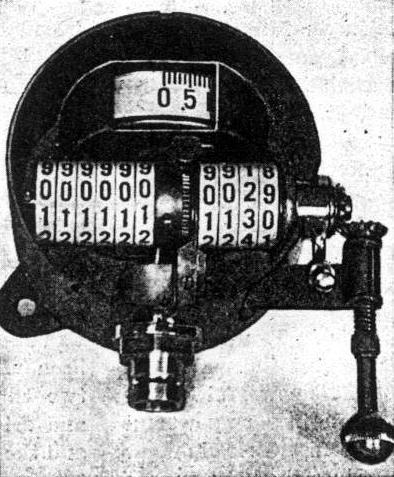

The new speedometer is unique in that it does not employ the centrifugal nor the magnetic principle as do the other types of speedometer in general use; instead, it relies on the friction of air as developed by metal surfaces. The two main components of the speedometer in question are a driving cup, which is rotated by power from one of the automobile wheels through the flexible shafting, and, suspended over and around it, a driven cup. The driven cup, which is also the indicating one since the numerals representing the miles per hour attained are marked on its periphery, is inverted over and around the driving cup, as will be noticed in one of the accompanying illustrations. This cup, as is also true of the driving cup, in reality consists of a double cup.

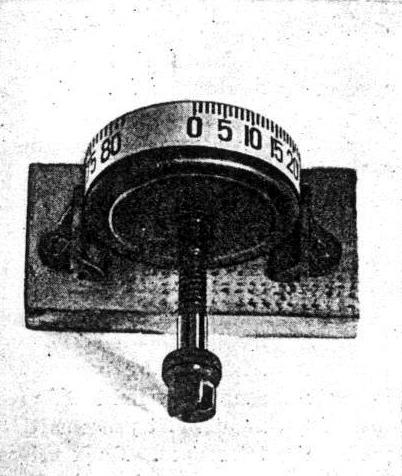

The driving cup of the speedometer comprises two concentric brass cups with a spacing of .108 centimeters between the two vertical walls, called "ribs" for convenience, both of which are rigidly mounted on a vertical shaft so as to revolve in perfect unison. Likewise the driven or indicating cup is made up of two aluminum cups attached together so as to form a single cup insofar as its mechanical operation is concerned. These cups are extremely light, being made of aluminum .008 centimeter thick. This means that 313 of these cup thicknesses would be required to total a thickness of 1 inch.

The driven cup when in position in the instrument has its inner rib floating in the annular space between the ribs of the brass cup, while the outer rib of the aluminum floats outside of the brass cup. There is an air space of .5 millimeter between the ribs of the brass and aluminum cups. In one of the accompanying views may be seen how the two cups are telescoped.

The operation of the new speedometer is of the utmost simplicity: the revolving of the brass cup generates the air friction which, were it not for a regulating hairspring serving normally to maintain the aluminum cup at the zero marking, would cause the latter to revolve; in other words, the air friction developed serves as a means of transferring the driving power from the brass cup to the aluminum cup. The hairspring is so adjusted as to permit the aluminum cup to be affected by the air friction in direct proportion to the speed of the brass cup, so that the reading of the instrument will be correct.

The air friction developed in the instrument has been proved to be directly proportional to the speed of the revolving cup. It is this fact that has made possible a uniform calibration without introducing compensating devices to gain this end. Comprehensive laboratory tests are reported to have proved that air friction is not influenced by heat, cold or altitude up to 10,000 feet. The revolving cups, contrary to expectations, do not have to be carried in an airtight compartment, and no sealing is necessary. The regulation between the tension of the hairspring and the tendency of the aluminum cup to rotate under the influence of the air friction is so delicate that the instrument indicates immediately all speed changes, and indicates as low as one half mile per hour. Yet the instrument is so sturdy that its accuracy is not affected by vibration in regular service.