TCBA Volume 20 - Issue 1

Page 12 of 18

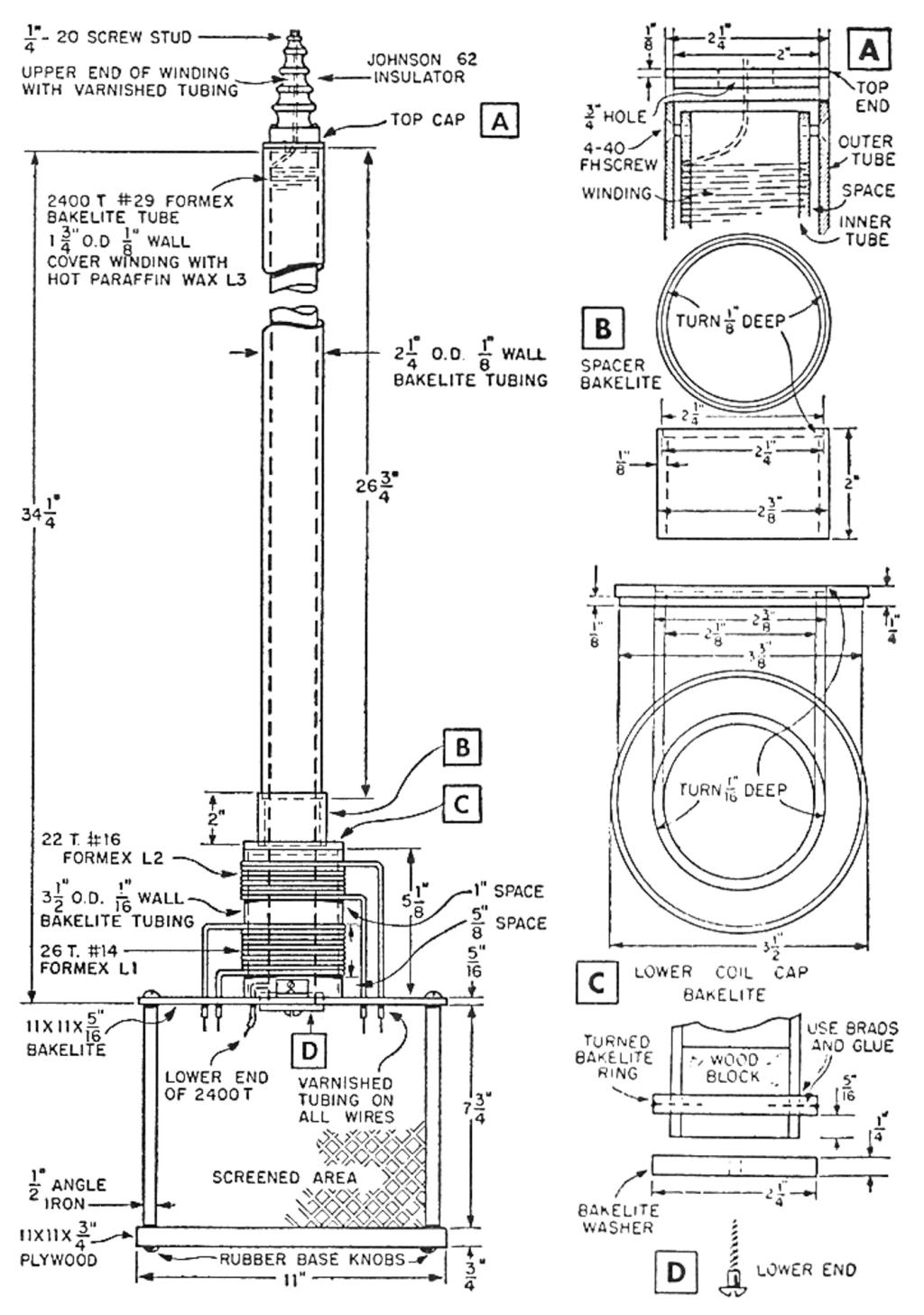

Materials List - Tesla Coil

- 1 pc. 5/16 sheet Bakelite (black) 11x11"

- 1 pc. Bakelite tubing, 1/8 wall, 2 1/4" O.D., 26 3/4" long

- 1 pc. Bakelite tubing, 1/8" wall, 1 3/4" O.D., 34 1/4" long

- If bakelite tubing is unavailable at this length, use polystyrene (best) or cardboard well soaked in hot paraffin wax (last choice)

- 1 pc. Bakelite tubing, 1/8" wall, 2 3/8" O.D., 2" long

- 1 pc. Bakelite tubing, 1/16" wall, 3 1/2" O.D., 5 1/8" long

- 1 pc. sheet Bakelite, 2 1/2x2 1/2x1/4". Top cap

- 1 pc. sheet Bakelite, 3 3/4x3 3/4x1/4". Lower coil cap

- 2 pcs. sheet Bakelite, 2x2x1/4". Washer, bottom of coil

- 1 Johnson #62 porcelain insulator and mounting ring

- 1 pc. plywood, 11x11x3/4". Base board

- 4 pcs. 1/2x1/2x9" angle iron

- 4 rubber base knobs

- 4 pcs. perforated sheet steel or aluminum. Base cage

- About 1/2 lb. #29 heavy Formex wire, or Formvar. (Heavy means insulation)

- About 25 ft. #16 Heavy Formex wire

- About 30 ft. #14 Heavy Formex wire

- Varnished tubing for wires under panel

- 1 plate transformer, 115 volts 60 cycles pri. 1200 volts sec. at 350 ma.

- 1 filament transformer, 115 volts 60 cycles pri. 7.5 volts at 8 amp. sec.

- 1 1250 ohm, 25 watt adjustable resistor

- 1 .0007-mfd., 1 - .0005-mfd., 1 - .0004-mfd., 3000-volt mica transmitting capacitors

- 1 .0008-mfd. 3000-volt mica transmitting capacitor

- 1 .005-mfd. 2500-volt mica transmitting capacitor

- 2 porcelain 4-pin sockets

- 4 1/2" porcelain spacers

- 1 fuse mount for 3AG glass fuse

- 1 10-amp. 3AG fuse

- 1 2-terminal Jones terminal strip 8 ft. #18 two wire rubber cord

- 1 attachment plug cap

- 2 Hytron 5514 transmitting tubes

- 2 S.P.S.T. toggle switches 6 amp., 115 volts

- 1 insulated ground terminal post (make from 10-32 screw, nut, washer and Bakelite thumb nut)

- Misc. wire, screws, nuts and so on

Material to make attachments for experiments taken from drawings

Sources of Supply

Radio and electrical parts - (Allied Radio, 833 West Jackson Blvd., Chicago 7, Ill., or Radio Shack Corp., 167 Washington St., Boston, Mass., or Hatry and Young, Inc., 811 Boylston St., Boston). Magnet wire - (Now in short supply. Try radio stores, electric motor repair shops, or Insulation and Wires, Inc., 1040 Tremont Street, Boston, Mass.). Sheet phenolic (Bakelite) and phenolic tubing - (Huse-Liberty Mica Company, 171 Camden Street, Boston, Mass. Forest Products Co., 194 Broadway, Cambridge, Mass.) Lucite tubing may also be used as an excellent substitute for Bakelite and is cheaper.

Turn the Bakelite washers and mounting discs for mounting both primary and secondary coils. Use varnish instead of cement to hold them together. When all parts are assembled and wired according to the schematic diagram (Fig. 9) cover the tall coil with a 2 1/4 in. O.D. x 1/8 in. Bakelite tube to protect the winding and help reduce radiation of the high-frequency current to the surrounding air. Connect the ground terminal to a water pipe or other ground connection. The coil will work, however, without this ground connection. To put the coil in operation, first throw switch #1 (Fig. 9), wait 30 seconds, then throw switch #2. This allows time for the Hytron tube filaments to warm up. On the first trial, connect a 0-500 ma d-c milliammeter from the center tap of the filament transformer to ground as shown in Fig. 9. Current reading on this meter should be 325-375 ma max. or something is wrong. Recheck wiring and make sure primary coil leads are connected right.

Let's get on with the experiments. With the coil operating properly, you should be getting a brush discharge from the top end of the coil about 4 in. high (Fig. 1). A spectacular sight is the rotating wire experiment which takes on added tempo with this more powerful coil. Use a 12-in. length of .006-.008-in. Nichrome wire shaped according to Fig. 11A. Fig. 3 shows the result of a very energetic whirling of the wire ends with bright lavender streamers coming out all along the wire and rotating in almost perfect 6-in. circles.