TCBA Volume 18 - Issue 1

Page 12 of 18

Techniques to Determine Optimum Spark Gap Break Rate

D.C. Cox, Resonance Research

E11870 Shadylane Rd., Baraboo, Wi 53913

Spark length is very dependent on pulses per second (pps) or break rate because the plasma has less time to cool off. Initial phase of plasma creation pumps a considerable amount of energy into the production of light, so the luminous factor is important from a purely aesthetic value. Power is required to form the plasma (potential for ionization). It is the power in the secondary inductor, not the potential, that really determines spark length. Up to now, I'm sure that you are with me.

Now enters the question that has been the subject among experimenters for some time - how to determine the optimum break rate. It will vary with each system. However, an experimenter can optimize the break rate or pps for a particular system. Up until now, experimenters have been discussing the secondary spark length. But to determine the optimum break rate for any system, another important factor must be considered - how many watt-seconds of energy is lost in the primary spark gap. In any large system, there is a tremendous amount of energy wasted forming the initial ionization as well as the production of heat and UV light. But attempting to measure the lost energy directly with electrical instrumentation is very difficult. However, there is a much easier way which we have used in the past in the analysis of our systems to determine optimum pps.

Remove the secondary inductor of your system. We must assume you have a rough idea of the load impedance your secondary inductor represents by o-scoping the waveform, looking for the 10 hz decay, and then determining loaded dynamic Q factor as John Couture has suggested - which is, of course, directly related to pi. In our experiments, we made an assumption that loaded operating impedance as seen by the primary inductor was around 30 ohms. If one scopes the current in the primary and compares this value with the secondary in place so a parallel resistor of equal value can be substituted to set the two currents equal and thus determine the exact dynamic operating load, we can then place the 30 ohm “Glo-bar” type resistor in parallel with the primary inductor so that it simulates the operating secondary load.

Now comes the fun part. Instead of using electrical instruments to measure the losses, one can employ a bit of chemistry (in particlar, calorimetry) to measure the losses. This works very well because the watt-second is directly equatable to calories of heat. In this test, certain constants are required (constant cap value, constant frequency, constant primary inductance, and constant average input power to the system). Resistance load in the primary simulates the Q factor the secondary coil would be if it were in place. At 2 pi radians per cycle, # of cycles x 2 pi = dynamic loaded Q of system. The idea here is to have all constants except one - the number of pps for the system. This becomes the variable for each test.

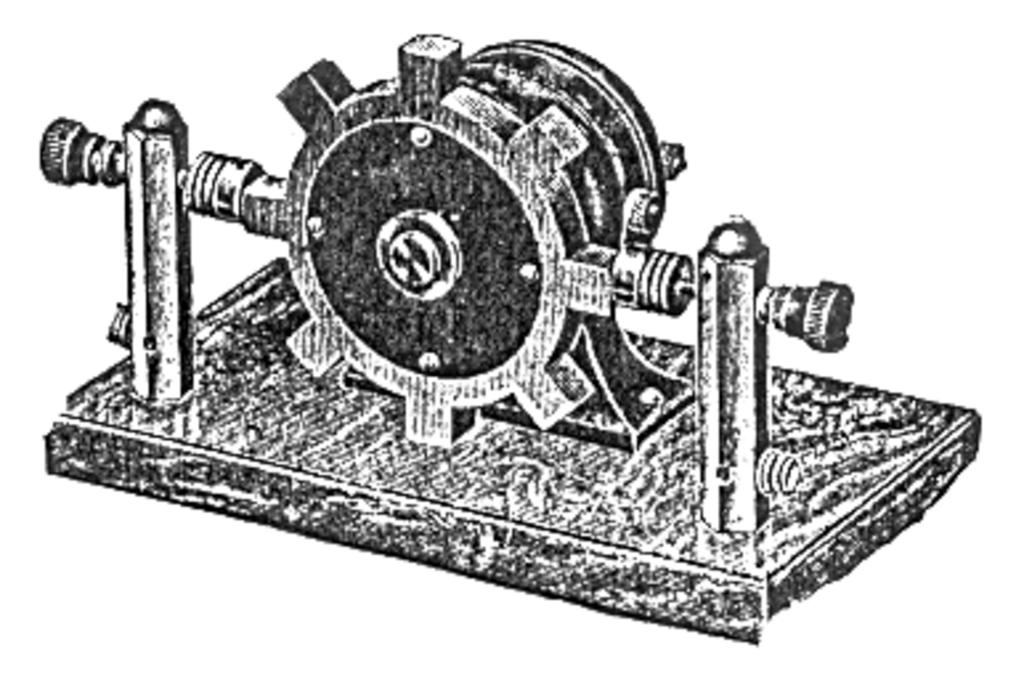

A thermistor (or thermocouple) is expoxied to the body of the resistor. Use a relay to drop the HV off quickly, and within 1/2 second switch on the leads from an analog meter to the thermistor or thermocouple to read the heat value in the resistor. Using a special sparkgap with “extra” stationary electrodes (that can be placed in series as necessary or using a speed control on your rotor) will allow you to take different heat values for each pps combination. I always feel the best way is to use a constant speed motor and just vary the number of series breaks with jumpers as you cannot always be sure all terminals are firing (one or two may skip which would give you false assumptions). The differential between these powers represents the losses in the primary spark gap.

For smaller or medium size systems, you can run the system in air and just run the oscillator for 5-10 seconds (be sure to accurately measure this time value which must be equal for each test). For large systems, we usually drop the big resistor into a small plastic tank filled with transformer oil and run it for 10 seconds. The oil prevents overheating of the resistor.

The idea here is to carefully achieve a good balance between the break rate which at higher power levels does produce longer sparks and the total combined losses each individual spark gap represents. The other variable, again, becomes the product constant of the cap size and pulse rate.