TCBA Volume 13 - Issue 1

Page 11 of 18

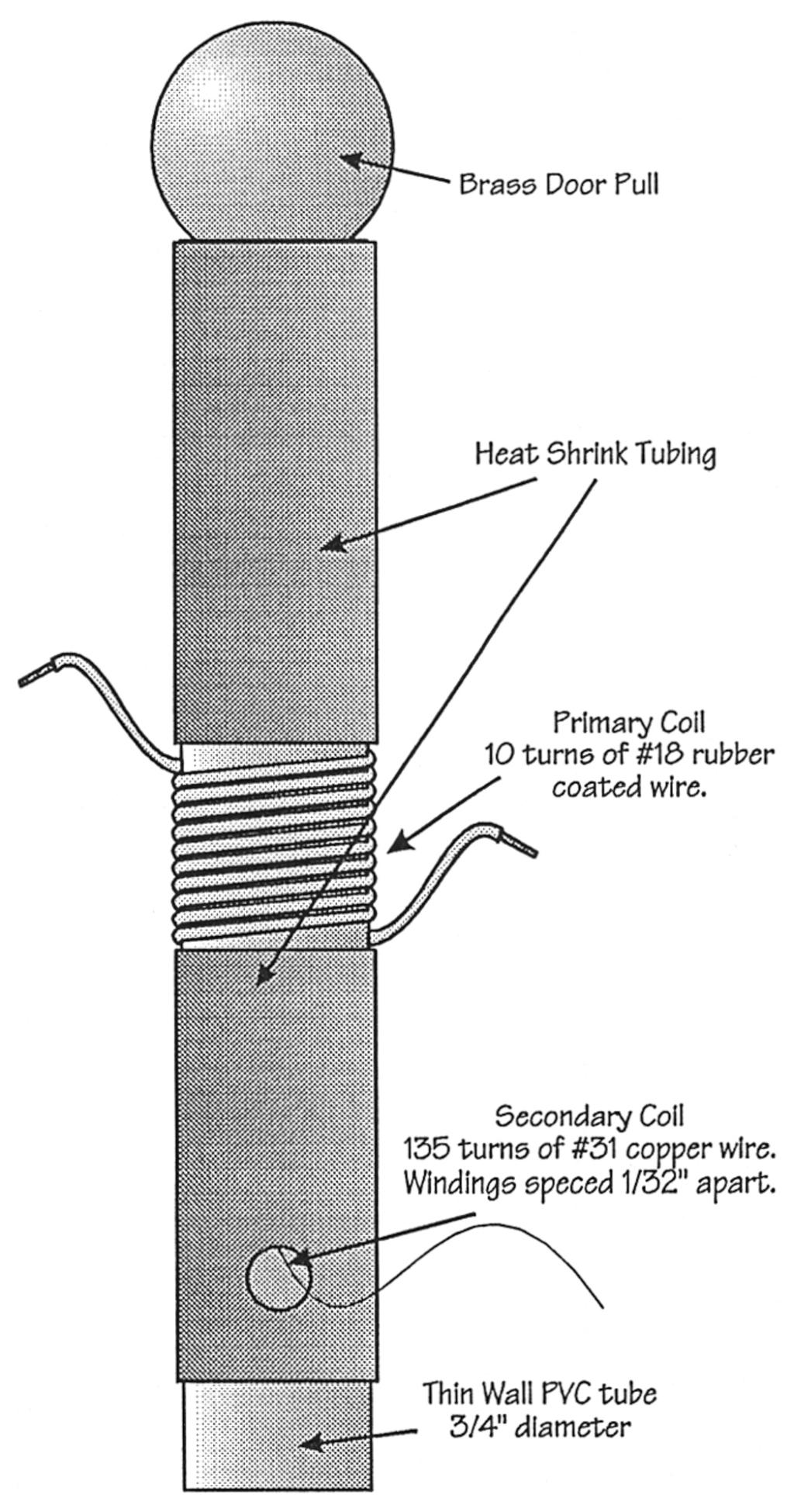

An Easily Constructed Tesla Coil With “Painless” Spark.

By Walt Noon (T.C.B.A. #1527)

The miniature Tesla Coil at the left can be assembled in less than 30 minutes yet exhibits some very interesting characteristics. When coupled to a simple induction coil, such as an auto coil driver setup, it is possible to achieve Tesla coil results at a variety of lower frequencies typical to induction coils.

Sparks from my basic auto coil driver increased from approximately 1/4" to over 1/2" inch in length when this coil was employed.

By carefully varying frequency and power output from the induction coil, it is possible to produce a spark which is painless to the touch. This opens up a variety of experiments such as Kirlian electrophotography as well as close examination of corona discharges and ionization of gasses.

To drive this small coil, I used the induction coil detailed in my article “Build A 40,000 Volt Induction Coil” which is available from Lindsay Publications. This driver allows variable frequency and power which are important for dialing in the “painless” spark.

To assemble the coil, begin by winding the secondary directly on the PVC building form. The secondary can be held in place with a thin application of lacquer. Next, wrap the entire secondary coil with three layers of a thin cotton cloth. Hold the cotton cloth in place by using heat shrink tubing as shown.

Wrap the primary, then attach the top terminal to one end of the secondary. Set it in place on the top of the form with a little silicone glue. The coil is ready to be used.

Note that both ends of the secondary are “hot.” A spark gap can be fashioned by bringing these close together, however, I usually use only the brass ball terminal.

The coil becomes more efficient at higher frequencies, however, the “painless” spark effect seems to be lost.

This coil was inspired by the “test tube” coil reprinted in R.A. Ford's Tesla Coil Secrets, available from Lindsay Publications Inc.