TCBA Volume 3 - Issue 1

Page 7 of 18

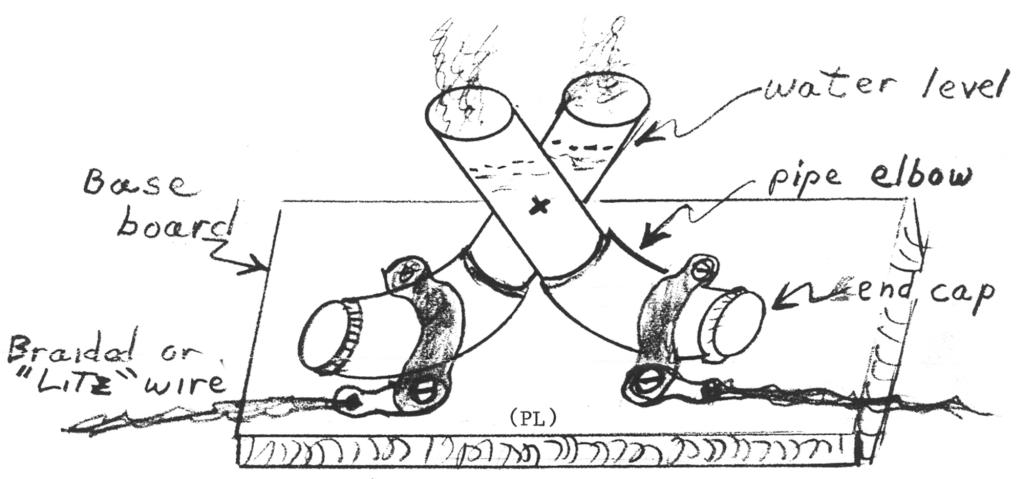

A Water Cooled Spark Gap Project

(using copper pipe fittings)

by

Peter Lefferts

1640 Decker Ave.

San Martin, CA

95046

Using water to cool a spark gap handling thousands of volts may sound unusual but the idea has shown to be simple, safe, reliable, and inexpensive. The principle works with powers ranging from 100 watts to 3KW. Above this, rotary gaps are the present answer.

The basic cooling concept came from my boy scout days when I saw a demonstration whereby water was boiled in a wax-coated sandwich bag over a fire. The principle used in this gap is similar - that is, the heat difference between the outside surface and the water doesn't reach combustible or damaging temperatures. Chances are, this spark gap will work on a short time basis. If one wants to run minutes at a time, the boiling might get violent. Here, longer pipes and filters should solve any splashing of hot water.

In my design, the simplicity of noncirculating water negates the need for pumps, tubing, and other complications. A wood base, a couple of metal clamps, and about $7 worth of copper plumbing parts are all that are needed. If you have some spare plumbing parts around, the cost can be even less. A propane soldering torch is used to solder the parts together.

I would appreciate hearing from anyone who has constructed and used this project. Questions from “Teslites” will be answered.